Corrosion Management

Corrosion management (CM) is a comprehensive process that governs the assessment, planning, execution, and improvement in managing corrosion related risk to ensure safe and reliable operation of existing and new assets. Corrosion Management System (CMS) is implemented universally in operating plants, as it is considered a dynamic approach to enhance asset integrity. CMS generally consist of 5 elements vis-à-vis:

- CM policy and strategy

- Organizational structure & responsibilities

- Planning & implementation

- Monitoring system performance

- Periodic review & audit

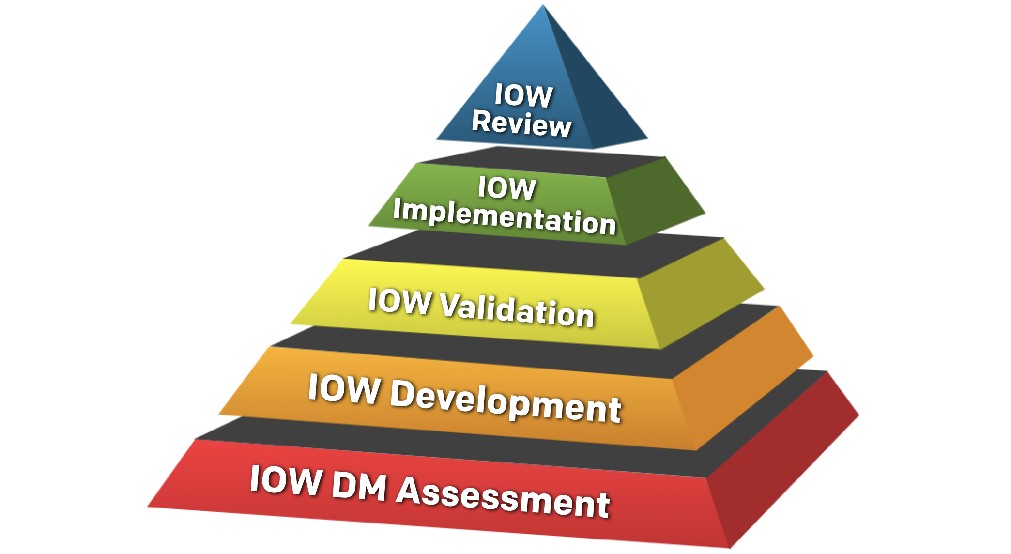

Over the years, it has been realized that a proper CMS implementation in operating units has led to control several damage mechanisms such as creep, microbial induced corrosion (MIC) etc., by regular periodic monitoring and inspection. One of the key documents in CMS is corrosion management program (CMP), the output of which is an Integrity Operating Window (IOW), Key Performance Indicators (KPIs) and Responsible, Accountable, Consult and Inform (RACI) chart. Developing a detailed CMP and establishing a comprehensive IOW is of paramount importance, as the parameters in IOW are monitored to control/manage corrosion. KPI shall be simple, measurable and realistic to achieve. KPI performance shall be gauged against the target and shall be subjected to management review annually.

Our professionals have developed several CMP documents, establishing comprehensive IOW, KPI & RACI for various offshore, refinery, petrochemical and fertilizer units. We have successfully implemented CMS in some operating units. We are also capable of conducting CMS audit to assess the effectiveness of CMS implementation in any operating plant as well as providing recommendations to improve CMS effectiveness and performance.